Instrumentation Division

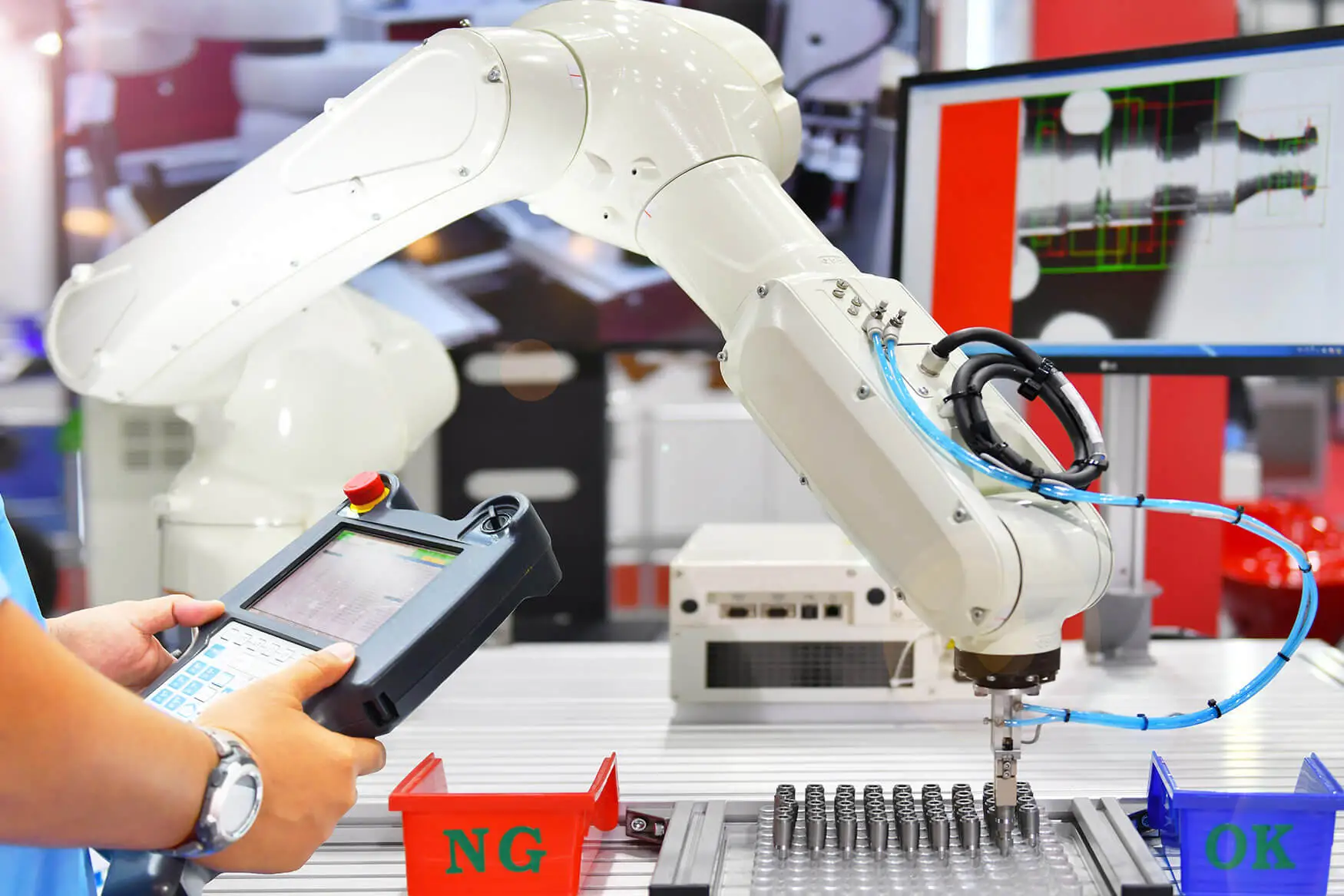

Precision Control for Complex Industrial Systems.

From calibration and installation to loop checks and system integration.

At Nitro Construction, our Electrical Division’s Instrumentation Services team provides the expertise needed to monitor, control, and optimize industrial processes with accuracy and reliability. From calibration and installation to loop checks and system integration, our highly trained instrumentation technicians deliver the precision required for modern industrial facilities. Whether working independently or as part of a larger electrical scope, Nitro ensures every system performs safely, efficiently, and exactly as designed.

Core Instrumentation Services

Our team delivers complete instrumentation solutions across new construction, maintenance, and retrofit projects:

Calibration & Testing

Ensuring instruments meet exact performance standards.

Control Panels & System Integration

Design, fabrication, and installation of control panels to integrate process systems.

Distributed Control Systems (DCS)

Installation, configuration, and commissioning of DCS architectures for process automation.

Programmable Logic Controllers (PLC)

Programming, installation, and troubleshooting for industrial control applications.

Instrument Tubing & Installation

Precision field installation for reliable data and process feedback.

Loop Checks & Startup Support

Comprehensive functional verification from I/O to control systems.

Environmental & Process Controls

Advanced monitoring for environmental compliance and system optimization.

Maintenance & Troubleshooting

Ongoing support and repairs to keep instrumentation systems operating at peak performance.

Integration with Electrical Services

Experience The Nitro Difference

With over 65 years of experience and a full-service approach, Nitro Construction Services provides turnkey electrical, mechanical, HVAC, fire protection, and fabrication solutions across the industrial and large commercial sectors.

01

Union Trained Workforce

02

Multi-Discipline Capabilities

03

Scalable Manpower

Need 100+ skilled trades on site? We have the size and structure to ramp up fast—without compromising safety or quality.

04

Advanced Training & Certifications

Nitro Construction Services' union workforce includes Including multiple Master Electricians and OEM technicians.

05

Safety-First Culture

06

Turnkey Project Delivery

From pre-fab to field install, our electrical division supports your schedule with offsite efficiency and onsite excellence.

The Nitro Difference

Instrument technicians with the precision, training, and experience your facility requires.

Electrical Instrumentation Experts. Measurable Results.

Control Your Process Systems Plant Assembly Line Data Center

Contact An Expert